GENERAL DESCRIPTION

1. Manufacturing specification : According to the design drawings and standard provided by Metis Group.

2. Roller width :1650mm

3. Speed : Max 30M/Min.

4. Driven power : Ac inverter motor, linkage control system

5. Voltage : 3 phases, 380V×50Hz

6. Motor power :about 70KW,Electric heating : about 18KW, Total power 82KW

7. Heating form :heat conduction oil ;hot air circulation

8. Tension control:10Kg/M—150Kg/M.

9. Apply to material :PU, PVC.

10. Dimension: L*W*H=35M * 3.5M * 3M

MACHINE MAIN ITEM LIST

A. EPC auto edge correcting unwinding system …………………………………....................................................…….…1SET

1. Type : Auto edge control, roller type moving way, two unwinding positions

2. Max unwinding diameter : ø1000mm

3. Machine frame and stand : steel plate weld structure.........................................................................................................1UNIT

4. Unwinding : shaft stand unit 4unit...............................................................................................................................................4UNIT

5. Unwinding shaft:38*38m/m square axis* ø89mm *1650mm, unwinding tube.......................................................... 2PCS

6. Tension control: endless band brake device.........................................................................................................................2UNITS

7. Chrome plating guiding roller and bearing.............................................................................................................................1UNIT

8. EPC auto-edge correcting device with oil hydraulic cylinder : ø63*300mm and 2HP oil hydraulic pump....1UNIT

B. Oil hydraulic type accumulator for 15 M length.........................................................................................................1SET

1. Type :oil hydraulic elevating control

2. Machine stand:160mm channel steel weld.............................................................................................................................1SET

3. Active guiding roller:ø88mm steel roller with chrome plating, with bearings....................................................7PIECES

4. Passive guiding roller:ø88mm steel roller with chrome plating, with bearings..................................................8PIECES

5. Active guiding roller fixed frame : 12mmT steel plate......................................................................................................2PIECES

6. Lifting/down oil hydraulic cylinder:ø80*1100mmST......................................................................................................2PIECES

7. Lifting/down pulley device............................................................................................................................................................4UNITS

8. Elevating device: chain wheel, chain, fix shaft, bearings, etc................................................................................................1SET

9. Limited switch....................................................................................................................................................................................2PIECES

10. Guiding roller:ø88 steel roller with chrome plating, with bearings.........................................................................3PIECES

11. Oil hydraulic driven device :oil case, motor, pump, pressure gauge,

adjusting valve and Safety valve etc,.................................................................................................................................................1UNIT

12. Control switch and oil hydraulic pipe line with in machine...............................................................................................1UNIT

13. Safety guard:40mm square tube weld................................................................................................................................2PIECES

14. Pressing traction roller:ø125mm rubber roller with bearings......................................................................................1PIECE

15. Pressing guiding roller:ø125 chrome plating roller with bearings ...........................................................................1PIECE

16. Pressing air cylinder:ø63*75mmST...........................................................................................................................................2UNITS

17. Pressing roller seat..........................................................................................................................................................................2UNITS

18. Air conditioning unit :switch valve and air pipeline construction with in machine.............................................11UNIT

19. Ø120 rubber roller with bearing................................................................................................................................................2PIECES

20. 10kg/m2 powder brake...................................................................................................................................................................1UNIT

21. Transmission gear wheel unit........................................................................................................................................................1UNIT

C. Three rollers printing machine (Customer-owned)

D. 18M vertical stretching unit.......................................................................................................................................1UNIT

1. Vertical keyboard driven roller, chain-type

2. Stretching range 1200 mm*1600mm

3. Stretching chain:RS,4”Pitch

4. Pin stenter:12#*12, needle-type...................................................................................................................................................1UNIT

5. Stretching chain rail :FC 25 casting............................................................................................................................................1UNIT

6. Rail fixed join plate device................................................................................................................................................................1UNIT

7. Stretching chain auto timing oiling device............................................................................................................................2UNITS

8. Rail moving roller bearing stand device....................................................................................................................................1UNIT

9. Rail bearing stand moving pole:100mmH steel..................................................................................................................1UNIT

10. Stretching chain tension controller...........................................................................................................................................2UNITS

11. Stretching rail entrance/exit fixed frame:12#channel steel weld................................................................................2UNITS

12. Pressing and traction brush roller:210mm∮.....................................................................................................................4PIECES

13. Pressing and traction seat device.............................................................................................................................................4UNITS

14. Pressing and traction air cylinder:50mm∮*50mmST........................................................................................................4PIECES

15. Switch valve and air pipeline construction with in machine.........................................................................................1UNIIT

16. Auto-edge correcting on rail entrance :light sensor type EPC driven motor and screw.....................................2UNITS

17. E.P.C 1/2HP driven motor and screw device...........................................................................................................................2UNITS

18. Rail width adjusting:38mm∮, to-and-fro type screw device.............................................................................................1UNIT

19. Width linkage adjusting:32mm∮linkage shaft and warm wheel device.................................................................1PIECE

20. Width adjusting 2HP driven motor and warm wheel reducer.....................................................................................1UNIT

21. Guiding roller:100mm∮stainless steel roller with bearings........................................................................................4PIECES

22. Oil holder:2mm steel plate weld..........................................................................................................................................2PIECES

23. Master driven15HP motor and warm wheel reducer........................................................................................................1UNIT

24. Safety cover & transmission unit..................................................................................................................................................1UNIT

E. 18M hot air circulation type drying oven.........................................................................................................................1UNIT

1. Type : 18M hot air circulation type drying oven ,auto-temperature control

2. Frame:100# square steel and plate ,subsection oven as a whole...................................................................................1UNIT

3. Heat insulation plate outside:δ1.5mm cold rolled plate...............................................................................................1UNIT

4. Insulation cotton label 120 grams, cold plate and insulation between the layers of aluminum paper to increase

the insulation effect......................................................................................................................................................................................1UNIT

5. Heat insulation plate inside:δ1.0mm galvanized sheet.....................................................................................................1UNIT

6. Heat insulation door moving device..........................................................................................................................................1UNIT

7. Oven explosion proof cleaning door.............................................................................................................................................5PIECES

8. Temperature control gauge :P.I.D electrical type...................................................................................................................3SETS

9. Temperature detector:resistance-typePT-100*900mmL..................................................................................................3PIECES

10. 20,0000 kilocalorie heat exchanger,:STB-35, with extended surface tube type..........................................................3SETS

11. Thermal energy converter suspension type strainer

12. Blast &inducing air pipeline:δ0.8mm galvanized sheet.............................................................................................3UNITS

13. Air exhaust and inducing pipeline:δ0.8mm galvanized sheet........................................................................................3UNITS

14. Air blasting, air exhausting, air circulation device, air flow adjusting device................................................................3UNITS

15. Air blasting unit inside:δ0.8mm galvanized sheet...........................................................................................................3UNITS

16. Air blasting:3½#blower and 5HP*4P driven motor unit...........................................................................................6UNITS

17. 2# multiple wings exhaust fan &2HP driven motor unit...............................................................................................3SETS

18. Each six meters have one insulation board , the bottom of the machine also has insulation board....................1UNIT

19. 1,5 m electric heating cover: heating power 18KW, manual lift, stop automatically stop heating.........................1UNIT

F. Cooling unit..................................................................................................................................................................................1SET

1. Type :water circulation cooling type

2. Machine frame:16#10# square steel...........................................................................................................................................1UNIT

3. Cooling roller:ø500mm stainless steel roller, with bearing , one in one out.........................................................4PIECES

4. 1.5"two-way water jointer ,valve and mental connecting hose.............................................................................8PIECES

5. Ø88mm stainless steel guiding roller.........................................................................................................................................1PIECE

6. 3HP driven motor and warm wheel reducer..................................................................................................................................1UNIT

7. Safety cover and transmission chain............................................................................................................................................1UNIT

8. Trimming machine: bilateral motor, bilateral round knife, adjustable width and width,

with a group of traction roller..................................................................................................................................................................1UNIT

G. Winder with gyral arms...........................................................................................................................................................1SET

1. Type :double winding axis

2. Max winding diameter:ø1000mm

3. Effective winding width:1550mm

4. Machine frame:120mm, channel steel and iron plate...............................................................................................................1SET

5. Central shaft steel shaft seat unit...................................................................................................................................................1UNIT

6. Safety collect and shaft stand unit................................................................................................................................................1UNIT

7. Winding frame:30mmT steel plate..............................................................................................................................................2PIECES

8. Winding:30*30mm *ø89mm winding tube, winding shaft seat...................................................................................1UNIT

9. 360 round turn rotary :big warm wheel and pole.................................................................................................................1UNIT

10. Guiding roller:ø88mm stainless steel roller with bearing...................................................................................................1PIECE

11. 5HP winding driven motor and warm wheel reducer............................................................................................................1UNIT

12. 3HP driven motor for gyral arms rotary and gear reducer.....................................................................................................1UNIT

13. Safety cover and transmission unit..................................................................................................................................................1UNIT

14. Electronic control panel.......................................................................................................................................................................1UNIT

15. 5HP inverter................................................................................................................................................................................................1SET

H. Electrical controlling box and control panel........................................................................................................................1SET

1. Controlling box:1.6mmT steel plate weld acrylic board in front ,each motor has light indication flow

2. Main control parts &f unction: motor between control unit , motor for blower , exhaust fanon/of and temperature control for drying oven

3. Composition of the cabinet :Including the buttons, ammeters voltmeters, electrical switches, nonfuse switches, temperature controller, wire casing internal wires, cooling fan etc.

4. Electrical component brand :Partial is from Japan

5. Control panel: to control the motor on/off, there are signal light, urgent stop button, buzzer, motor speed indicator etc.

I. Air and transmission system.................................................................................................................................................1UNIT

1) Pneumatic pressure part :

(a) Tubing of air compressor to switches of air cylinder

(b) Tubing of air compressor to inflation of air expanding shaft

(c) Add two sets of three-point compose(pressure regulating + draining +oil filter) to air feeding point

(d) Flow switch at all cylinders, assembly of accessories, solenoid valve, relay ,etc.

2) Transmission part :

(1)Cone belt part :

A. Belt pulleys for fixation

B. Cone belt for installation

(2)Chain pitch wheel part :

A. Chain pitch wheel for fixation.

B. Chain for installation and tightness

C. Add lubrication to all gear and chain

J. Machine surface processing

1.Processed with KEBAO rust remover.

2.Plaster, burnish to level.

3. Advanced airbrush painting for two times.

4. Machine color : Blue and grey white color.

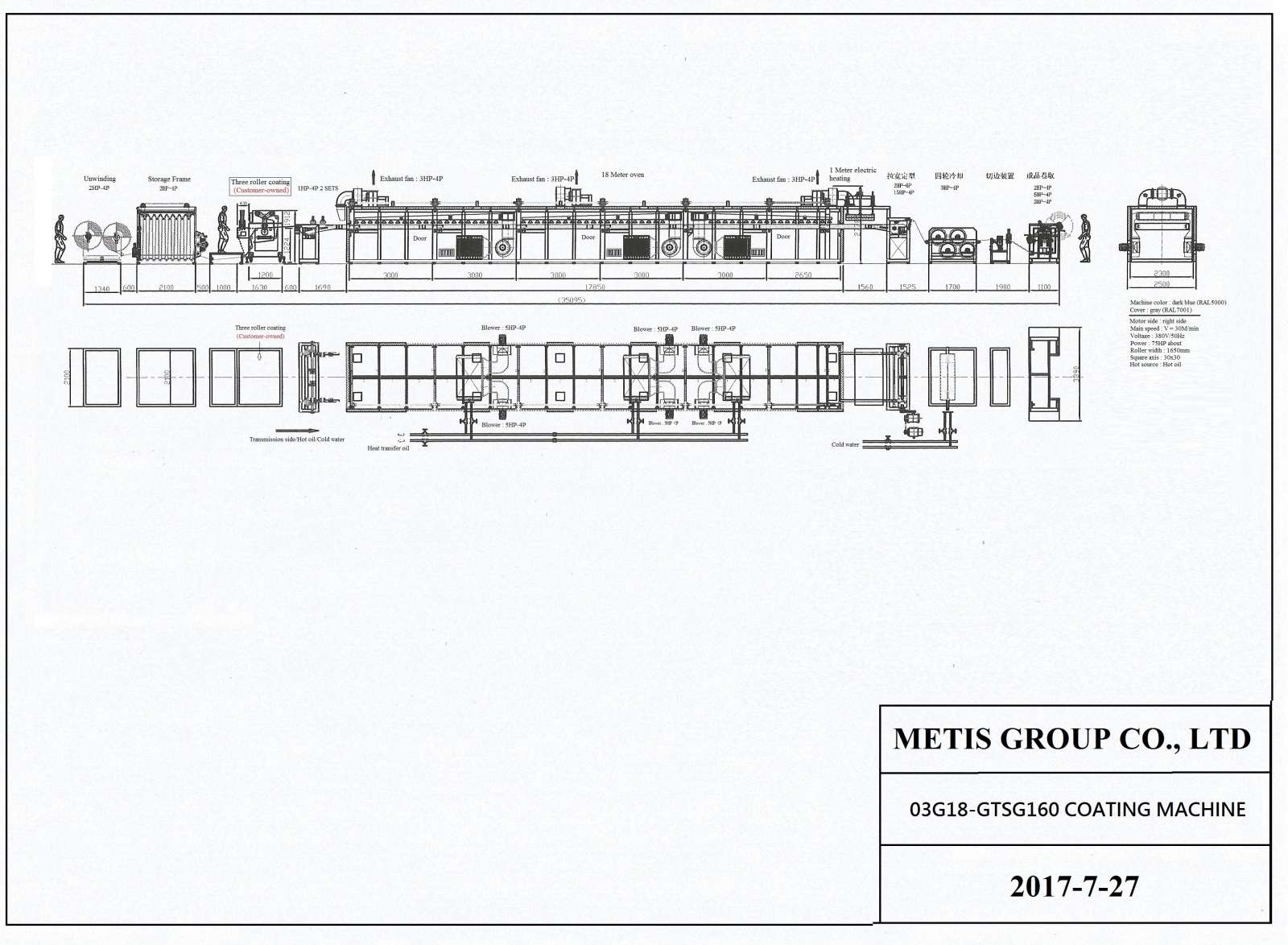

MACHINE DRAWING